|

|

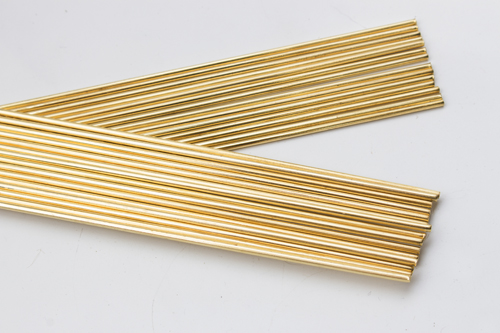

Copper-Zinc brazing alloys are suitable for gas-flame brazing, high temperature brazing,salt bath dip brazing of copper and copper alloys, nickel, cast iron and hard alloys. While brazing by oxyacetylene, to heat with oxidized flame quickly can lessen evaporation of Zinc and prevent gas porosity due to over-oxidization. The optimum joint gap should be 0.025-0.1mm. Flux is also necessary for good seam.

Attention:The residue such as grease,oxide etc on the surface and connection must be removed strictly before the brazing.

| 中国标准牌号 Chinese Standard |

相当牌号 Equivalent Grade |

化学成分(Wt%) Composition |

熔化温度范围(℃) Melting Range |

主要特性及用途 Characteristics and Application |

|||||||

| 产品样本牌号 | AWS A5.8 | Cu | Zn | Mn | Sn | Fe | Si | 固相线 Solidus |

液相线 Liquidus |

||

| B-Cu58ZnMn | 料105 | ___ | 57 ~ 59 |

余 rem. | 3.7 ~ 4.3 |

___ | 0.15 | ___ | 880 | 909 | 锰可提高钎料的强度、延性和对硬质合金的润湿能力,用于硬质合金刀具、模具及采矿工具的钎焊。 |

| B-Cu60ZnSn-R | 丝 221 | RBCuZn-A | 59 ~ 61 |

余 rem. | ___ | 0.8 ~ 1.2 |

___ | 0.15 ~ 0.35 |

890 | 905 | 可取代H62钎料以获得更致密的钎缝,尚可作为气焊黄铜用的焊丝。 |

| B-Cu48ZnNi-R | ___ | RBCuZn-D | 46 ~ 50 |

余 rem. | ___ | Ni 9.0 ~ 11.0 |

___ | 0.04 ~ 0.25 |

921 | 935 | 用于有一定耐热要求的低碳钢、铸铁、镍合金零件的钎焊,对硬质合金工具也有良好的润湿能力。 |